Introduction In the rapidly evolving educational sector, leveraging technology to enhance efficiency and productivity is more crucial than ever. As an educational institute, managing thousands of documents is par of the course, particularly during admissions...

📝 Advanced Tool for Document Verification Automation in Manufacturing: Unlocking Efficiency and Accuracy 🔍✅

What if I say there is actually one AI-supported software that can extract the data from documents and verify it? Yes, it exists, the software can extract the information from the document and can tell you if the document is as per pre-defined requirements or not.

As you can imagine, this software not only helps in automating the industrial manufacturing processes right from Raw Material verification to Final label review but also saves the data to give you insights on process capability and for improving the process to attain operational excellence.

With its wide array of features, the tool helps in two major pillars of Industry 4.0, automation and operational excellence.

Introduction:

As the manufacturing industry moves towards Industry 4.0, the need for automation and digitization is becoming increasingly important. With advancements in artificial intelligence (AI) and machine learning (ML), businesses can now leverage powerful software tools to verify documents and automate various processes.

One such tool which is helping industries in progressing towards smart automation is Automated document verification software. The tool can extract information from documents and verify them against predefined requirements or available databases.

Now we know what the document verification tool is, let us know more about the features that this AI-supported document verification tool has:

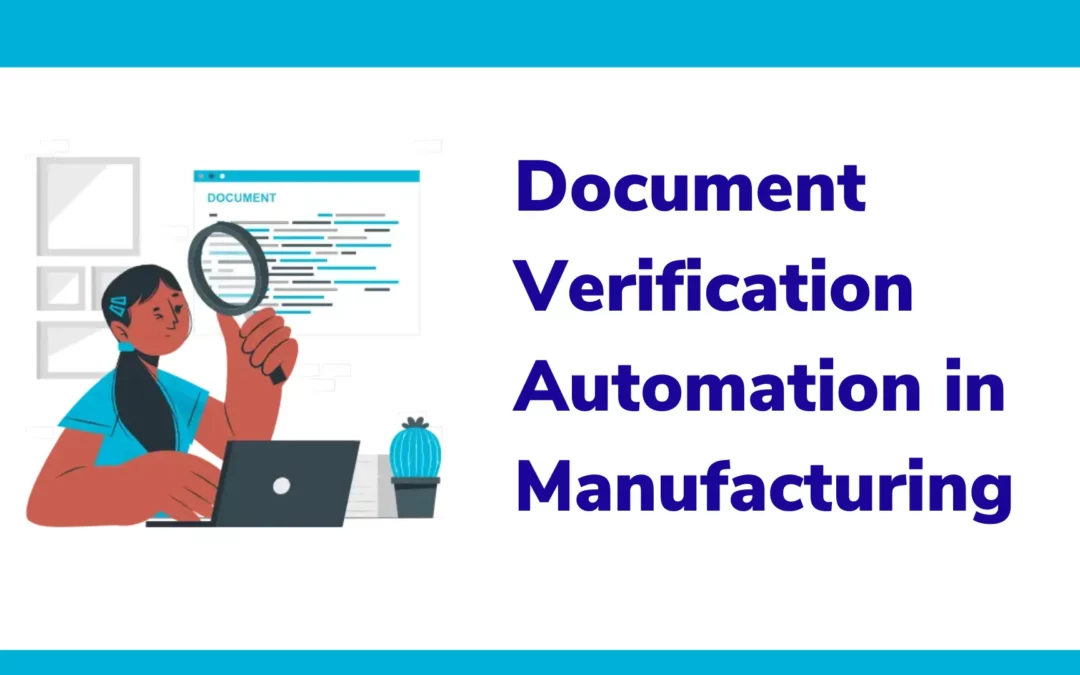

4 must-have features of document verification system for manufacturing automation–

1. Accurate data extraction for document verification:

Accuracy is highly important in the document verification process as it is directly linked to the reliability of the process.

The tool has a high degree of accuracy in extracting data from various types of documents, such as PDFs, images, and scanned documents. This has become possible with robust machine learning algorithms and natural language processing capabilities. System should be able to extract information of Identity from the document.

2. Customizable rule sets for verification:

Based on the scale of operation, the system might need to verify 100s of different types of documents, it is a must for the tool to meet the need of verifying custom documents.

The tool allows users to create customizable rule sets that define what data is extracted and how it is verified. This allows for greater flexibility in adapting the tool to different use cases and industries. The tool learns from the sample data, once the data is fed to the system, the system becomes capable of verifying any such documents in future.

3. Integration with existing systems:

It is always preferable to improve the existing set-up than installing a whole new set-up, especially in the manufacturing environment.

The tool can integrate with existing systems, such as ERP, CRM, and other manufacturing systems, to facilitate data transfer and automate workflows. This feature greatly helps in making the implementation smoother as the data migration task from the existing to a new system for document verification gets nullified.

4. Real-time monitoring and reporting:

In-process document verification is the key to identifying the mistakes in the process or documentation and mitigating the risk in finished goods.

The tool provides real-time monitoring and reporting of the document verification and data extraction process. This allows users to quickly identify and address any issues or errors that arise.

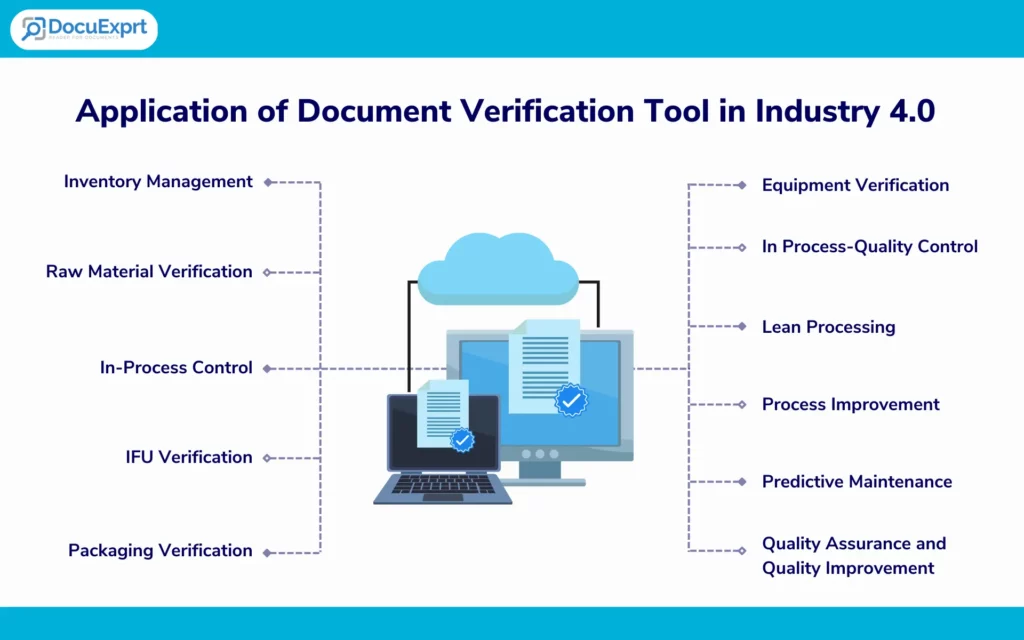

Applications of document verification tools in manufacturing environments for automation that supports Industry 4.0 objectives:

Inventory Management:

The software can verify documents related to inventory management, such as purchase orders, invoices, and bills of lading, to ensure that the correct items are being received and recorded. Document verification can be done in real-time. Further, the data can be extracted and saved in the form of an Excel sheet for future reference and better data management.

Raw Material Verification:

The software can verify the documents related to raw materials, such as material safety data sheets (MSDS) and certificates of analysis (COA), to ensure that the right materials are being used in the manufacturing process. Raw material verification is a very important process as it directly impacts the final product being manufactured.

In-Process Control:

The software can verify different types of documents related to in-process control, such as work instructions, process control plans, and quality control reports, to ensure that the manufacturing process is meeting the required specifications. In industries, the in-process documents are usually reviewed manually, if the manual controls are missed, this may lead to issues with the final product that increases the financial and customer risks. Automating this verification greatly helps in reducing the chances of manual verification errors.

IFU Verification:

For the majority of products, Instructions for use (IFUs) are a very important component of the packaging. These IFUs are critical to guide the user on how to use the product, use of IFUs is dominant in the food, pharmaceutical and medical devices industries. The IFU verification process is largely done manually, the allocated personnel reads through the IFU completely as part of finished good (FG) testing which turns out to be a time-consuming, tedious and error-prone process.

The software can verify documents related to instructions for use (IFU), such as user manuals and product labels, to ensure that they are accurate and comply with regulatory requirements.

Packaging Verification:

The software can verify documents related to packaging, such as packaging specifications, artwork text, and labels, to ensure that they are accurate and comply with regulatory requirements.

This verification helps in identifying if or not the correct information is printed on the final package or not. This process is usually done in industries in a semi-automatic way by installing the vision systems on the final packaging lines, these vision systems verify a few variable components like batch number, lot number, manufacturing date and expiry date.

The document verification tool can greatly help in identifying and verifying the whole information on samples without adding to operation time.

Details on the cartons of the product remain to be highly regulated parts of the products, automation of the packaging verification greatly helps in reducing the operation time while remaining 100% compliant with the regulations laid down by authorities (Like FSSAI, FDA or standard acts like LMA).

Equipment Verification:

Calibration and maintenance of the equipment are one of the best ways you keep your equipment in a manufacturing-ready state. The software can verify documents related to equipment, such as maintenance records, calibration certificates, and inspection reports, to ensure that the equipment is operating properly and meeting the required specifications.

Document verification software can greatly benefit the manufacturing industry by automating document verification and ensuring compliance with regulatory requirements. By leveraging the power of AI and ML, businesses can streamline their operations and improve the quality and efficiency of their manufacturing processes.

The document verification tool has a unique ability to not just extract the data, but also to validate the extracted data against the requirement. This greatly helps as the majority of the operations in the industry require process parameters to be within a certain range.

Let’s take a look at a few more applications of this document verification tool in manufacturing:

In Process- Quality Control:

The software can extract data from inspection reports and compare it with the quality control database in Excel to ensure that the products are meeting the required quality standards.

For example, at the end of the powder mixing stage, a report is produced by the system that tells about the process parameters like speed and frequency of rotation, time of rotation and amount of powder loaded in the mixer.

For getting the final mixture of desired quality, the speed, frequency and amount of powder in the mixer must be within the defined range. Once the data of required ranges are fed into the document verification tool, after each and every mixing run, the document verification tool can check after each and every run if the process was done rightly or not.

Thus, in case the process is done wrongly, that can save a lot of time, effort and loss made by leading to a nonconforming product at the end.

Lean Processing in the manufacturing environment:

The software can extract data from production reports and compare it with the production database in Excel to identify areas where waste can be reduced and efficiency can be improved. This is greatly helpful in yield improvement and waste reduction. In routine processing, the data of wastage is logged in the manual format and makes the supervisor and management miss the key insights on how the waste could be minimized by making the process more efficient.

Process Improvement:

The software can extract and save the process data that can be used to improve the process, which in other words is called operational excellence.

By leveraging the data extraction and comparison feature of this tool, manufacturers can not only automate document verification, but also improve their operations and processes in a variety of areas. This can lead to greater efficiency, cost savings, and ultimately, increased competitiveness in the marketplace. Document Validation can become streamlined task.

Predictive Maintenance:

The data of current manufacturing can be leveraged to predict any possible future failures and prevent them.

By extracting data from maintenance records and equipment performance reports, manufacturers can create a digital database of equipment performance and use this data to predict when maintenance is needed, preventing equipment breakdowns and reducing downtime.

Quality Assurance and Quality Improvement:

By extracting data from quality control reports and defect logs, manufacturers can create a digital database of quality performance and use this data to identify trends and patterns in defects, improving quality control processes and reducing the risk of quality issues.

By leveraging the data extraction feature of this tool, manufacturers can create a powerful digital database of manufacturing data that can be used for a variety of applications, ultimately improving efficiency, reducing costs, and increasing competitiveness.

The application of document verification software spans all industries like food, beverage, pharmaceutical, medical devices and automobile industries to count a few.

Here’s a case study on how a car manufacturing company used AI-powered document verification and data extraction software to improve their manufacturing process.

Case Study: AI-Powered Document Verification and Data Extraction Software in Car Manufacturing Automation

Overview

A major car manufacturing company was facing a challenge in their manufacturing process. They were struggling to keep up with the increasing demand for their cars while maintaining the quality and accuracy of their production. They needed a solution that could help them automate their manufacturing process and reduce the risk of errors and delays.

Solution

The car manufacturer decided to implement an AI-powered document verification and data extraction software that could automatically verify the accuracy and completeness of manufacturing documents, such as purchase orders, production reports, and quality control records.

The software could also extract relevant data from these documents and compare it with the existing data in their database, ensuring that all information was up-to-date and accurate.

Implementation

The implementation process was smooth and efficient. The software was integrated into existing manufacturing processes, allowing the documents to be automatically verified and the relevant data to be extracted and compared with their existing database.

Results

After implementing the AI-powered software, the company saw significant improvements in their manufacturing process. Here are some of the key results:

Higher accuracy:

The software was able to identify and correct errors in the manufacturing documents, ensuring that all data was accurate and up-to-date. This reduced the risk of errors and delays in the manufacturing process.

Better efficiency:

By automating the document verification and data extraction process, the company was able to save time and improve efficiency in its manufacturing process. This allowed them to keep up with the increasing demand for their cars while maintaining quality and accuracy.

Reduced costs:

The software helped the manufacturer to reduce costs by eliminating the need for manual document verification and data entry. This also reduced the risk of errors and delays, which could have resulted in additional costs.

Improved quality:

The software allowed the manufacturer to maintain a high level of quality in their manufacturing process by ensuring that all data was accurate and up-to-date. This reduced the risk of quality issues and helped to maintain customer satisfaction.

Takeaway of the success case

The implementation of AI-powered document verification and data extraction software helped the manufacturer to improve their manufacturing process and maintain their competitiveness in the market. The software improved accuracy, increased efficiency, reduced costs, and improved quality, ultimately leading to a more streamlined and effective manufacturing process. Manufacturing automation is one of the greatest revolutions that have happened in the last few decades, AI document verification tool is yet another example of such a breakthrough.

Conclusion:

The advantages of document verification tools are many, right from automation to the processes for supporting lean manufacturing to data collection for workflow and process improvement. With the advent of AI and the introduction of tools like DocuExprt, it is the best time for industries to utilize the tools which are ‘nice to have’ now, but will soon become ‘must have’ to remain competitive in the world of manufacturing.